Car Paint Protection

Give your car the premium paint protection it deserves with professionally applied ceramic coatings.

or give us a call on (02) 9639 5555

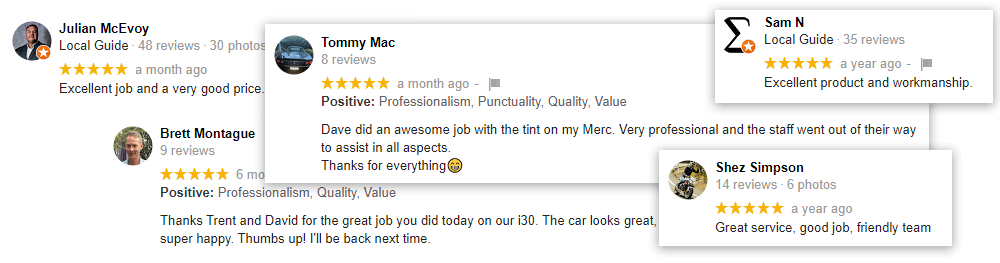

100+ Five Star Reviews

Castle Hill’s Highest Rated Ceramic Coating Specialists

Revolutionary Ceramic Coatings

One of the most common questions we get asked is, are ceramic coatings worth it? So let’s get into some of the detail so you can make an educated decision. Ceramic coatings represent a revolutionary advancement in vehicle protection. Ceramic coatings work by enhancing paintwork and ensuring your vehicle always has a deep, mirror gloss.

Your car will shine brighter than it ever has, while also offering water beading properties that will repel dirt, oil, dust, and road grime to allow for easier maintenance and cleaning.

With specific ceramic coatings for paint, vinyl wraps, glass and rims, it’s never been easier to protect and keep your car looking newer and cleaner for longer. The longevity of your ceramic coating will depend on what type of coating you choose, some last a few years some are more permanent and, once applied, can only be removed through sanding or buffing.

We have multiple coatings available in store, meaning we have a coating available within almost any budget. We’ll also take the time to teach you how to maintain your ceramic coating to ensure it serves you for years to come.

or give us a call on (02) 9639 5555

Complete Gtechniq Range

Industry leading ceramic paint protection

We are proud to announce our new partnership with Gtechniq Australia, giving us full access to the complete Gtechniq range of protective coatings. Gtechniq are global leaders in surface science and have engineered and developed protective coatings for both interior and exterior applications on vehicles since 2001.

Gtechniq became famous for their industry leading ceramic paint protection coatings, which provide unmatched performance and durability. Gtechniq guarantee their ceramic paint coatings for 3, 5 or 9 years, depending on the coating applied. Never has it been easier to give your car the best possible protection for as long as you plan on keeping your vehicle!

FAQs

Application process…

Applying ceramic coating.

A thick coating is allowed to set.

After buffing off with a soft microfibre its easy to see the added level of gloss and depth compared to the untreated section of the bonnet.

Ceramic Glass Coatings

Ceramic glass coatings protect your glass from water marks and fallout. Visibility during rain is greatly improved and this means added safety benefits during heavy downpours. Rather than water pooling on the windscreen and impairing visibility, the hydrophobic layer means that tiny beads of water will be instantly blown off your windscreen. In many cases, a ceramic coated windscreen reduces the need to even use your windscreen wipers at all!

or give us a call on (02) 9639 5555

Wheel Coatings

The rims and wheels are the hardest part of your car to keep clean. This is particularly true on performance cars with oversized brakes and intricate rim designs with hard to reach places. Brake dust is extremely corrosive and eats into even the strongest of powder coated and painted finishes.

After a wheel is coated with our ceramic wheel coating, cleaning wheels becomes a breeze and will be less frequently required. In most cases, brake dust can be removed with just a hose or pressure washer. For heavily soiled wheels, gentle agitation with a soapy solution may still be required. Once washed, the rim will be returned to its clean and smooth ceramic coated finish, ready to again repel brake dust and contaminants.

or give us a call on (02) 9639 5555

Vinyl Wrap and PPF Coatings

Vinyl wraps and PPF can’t be protected with the same ceramic coatings as painted surfaces . Special coatings for vinyl and PPF have now been developed, so wraps can also have the same level of protection as the rest of your vehicle. These wrap ceramic coatings improve dirt and water repelling and also help to prevent fading and yellowing of the wraps once applied.

or give us a call on (02) 9639 5555